Honeycomb ceramic filter

Application :

It Honeycomb ceramic filters are designed for filtration of cast iron and nonferrous alloy. It has the characteristics: larger specific surface, high mechanical strength, and perfect heat-resistance performance. It can make the following result through filter: Purify metal liquid and get ride of non- metal impurity and gas. Make the filling type of the metal liquid steady and reduce the swirl. Simplify the pouring system and improve the producing rate. Reduce the air vent of castings and optimize and thin out metal organization. Improve surface quality of castings and mechanical performance. Reduce the rejection rate of castings, reduce the surplus of processing, raise the life span of the cutter and reduce casting cost.

Features:

Properties:

Density (g/cm3) :0.7--1.8

Compressive Strength(MPa) :>15

Coefficient of Thermal Expansion: <5x10-6k-1

Impact Thermal Resistance(800ºC):>5

Modulus of Rupture(MPa): 1.3--1.6

Softening Temperature Meet various casting temperature

Regular Sizes and Filtration Capacity

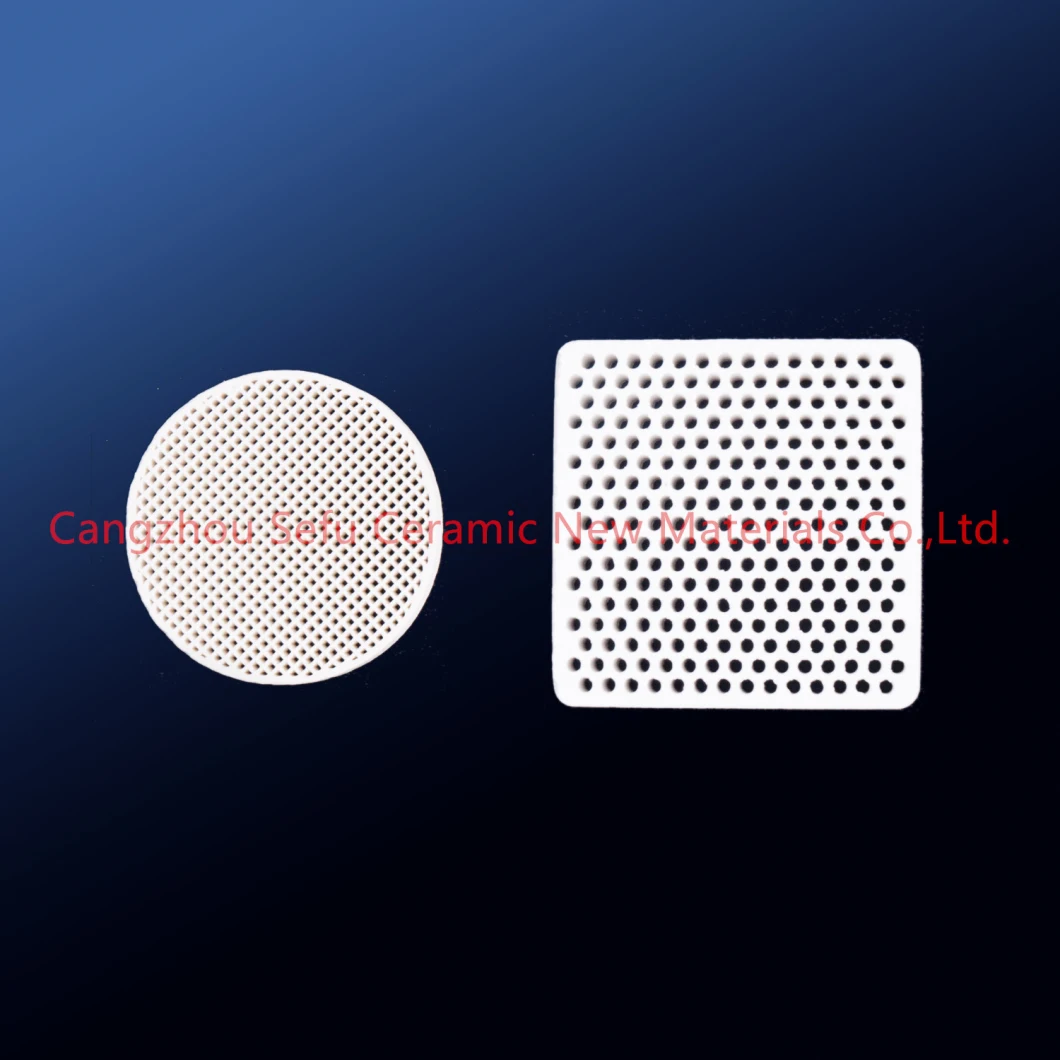

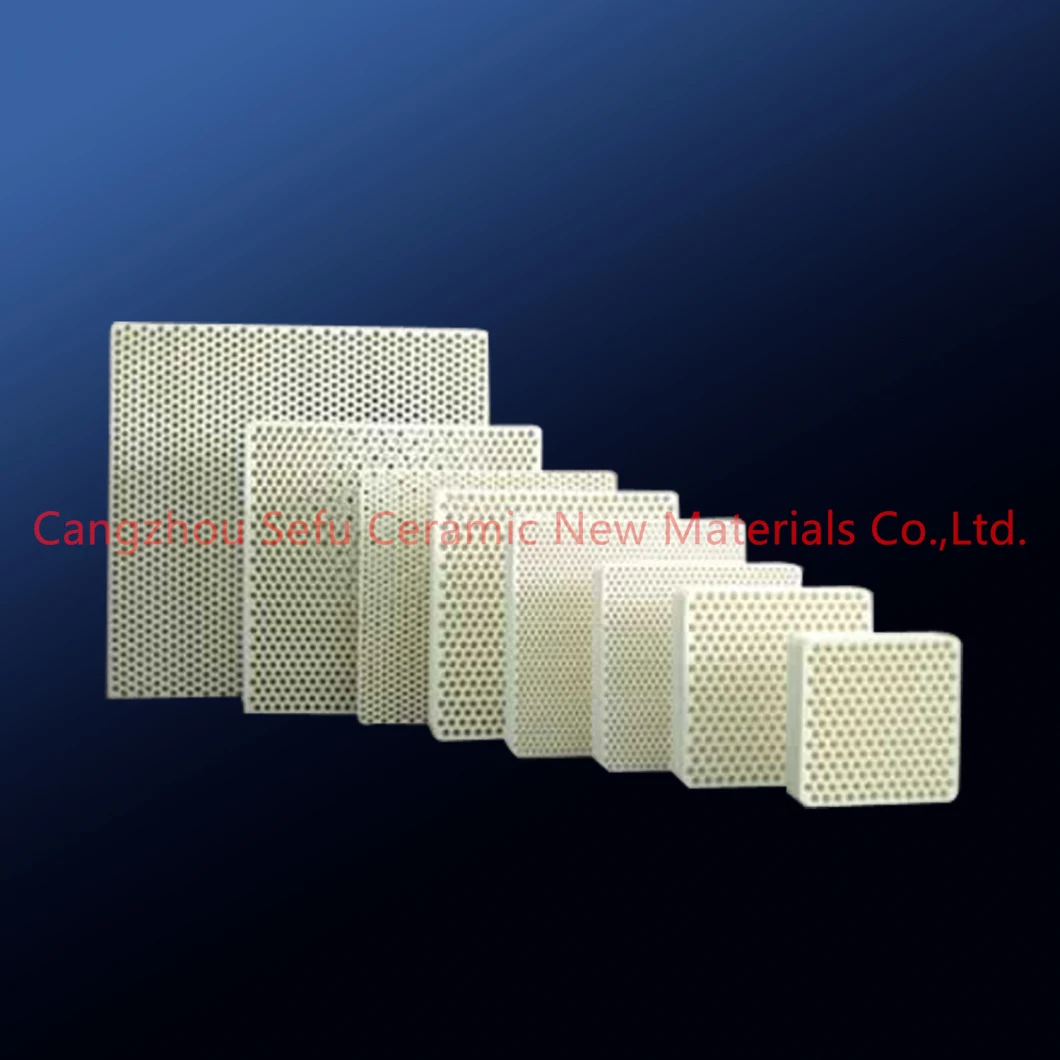

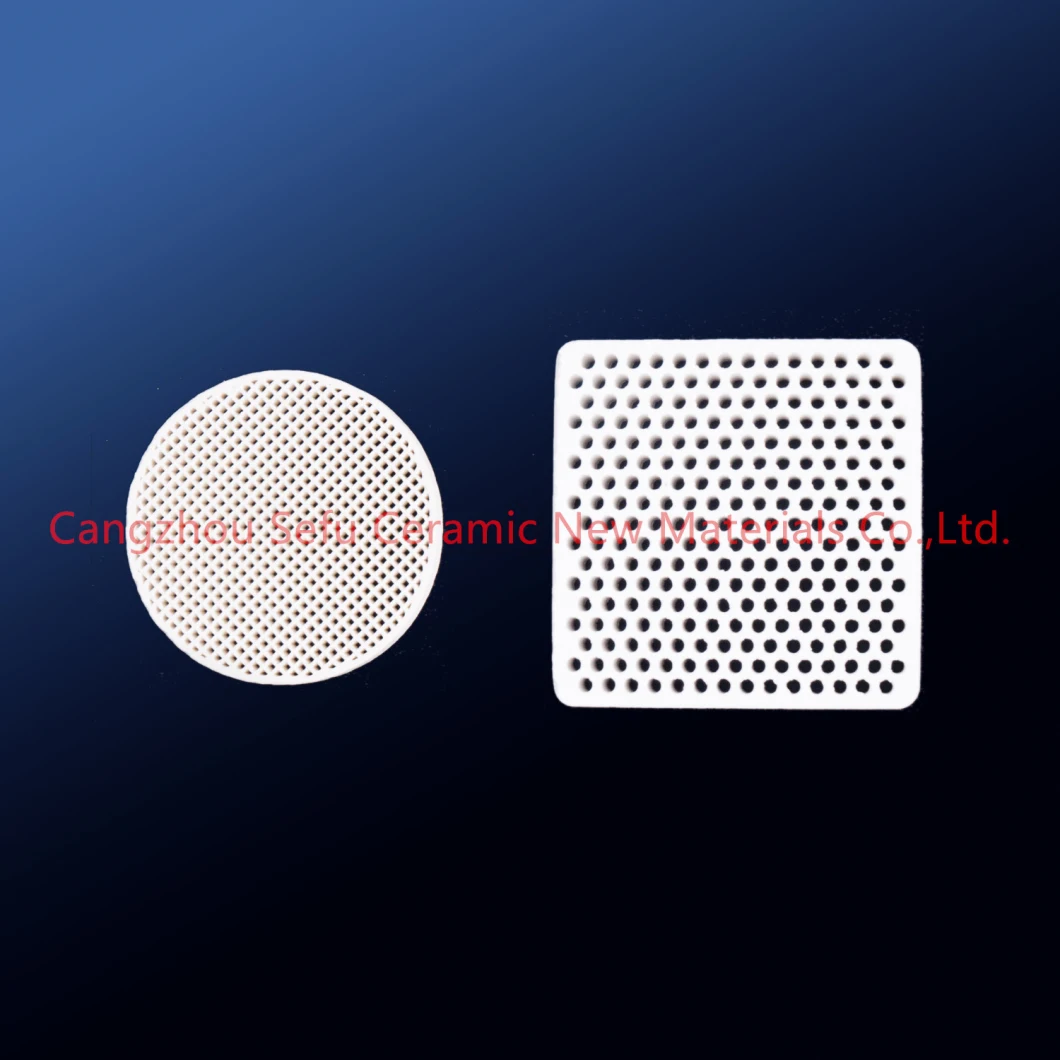

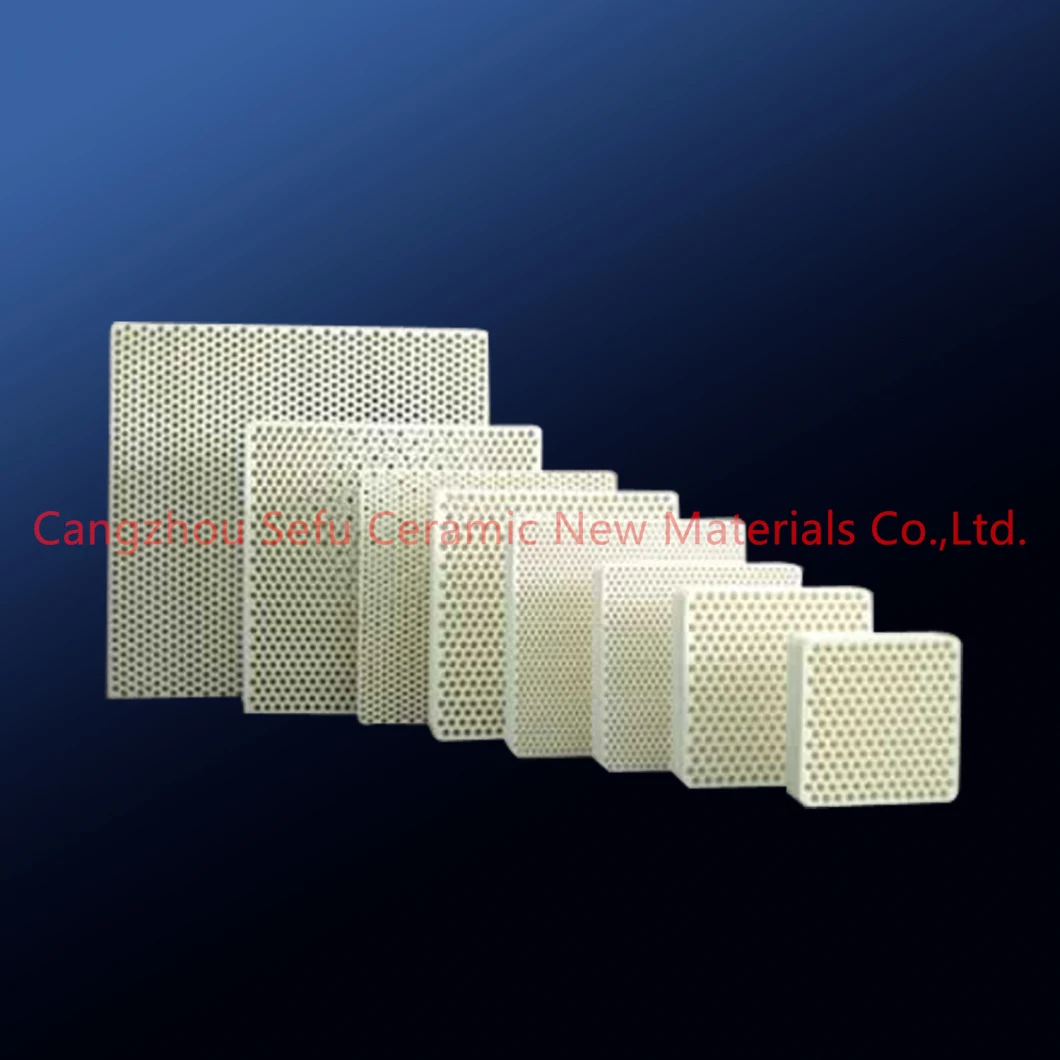

Detailed Images

Shipping

Lead time: 10-15days after signed the contract

Packing

FAQ

Q: Are you Factory?

A: Definitely, we are factory. Welcome to visit us!

Q: What Parameters should I provide to you for proper quotation?

A: Application, pore size, dimension, color, quantity, packing requirements, trade terms.

Q:How can you control your quality?

A:For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and we have the quality certificates with ISO9001.

Q: What is your lead time?

It usually needs about 15- 20 days after receiving the PO.

Q: Do you provide Samples?

A: Yes, our factory provide samples for testing, pls send detail parameters to us. (if customized, with drawing is best) The samples will be charged or free according to the specific requirements.

Q: What's the Payment Terms?

A: We accept T/T, L/C, West Union, etc.

Q: How can I get samples?

A: We are honor to offer you the samples.

Q: What about your Packing?

A: We provide plastic bag, woven bag, carton box, pallet, etc. OEM packing available too.

Q: Do you have R&D services?

A: Yes, we have R&D department to assist you in new product development.

Q:Does your company accept customization?

A:We accept OEM service.

Q:Can we visit your company?

A:Yes, for sure, you are welcome to visit our company.

Contact us

Cangzhou Sefu Ceraic New Materials Co.,Ltd.

Application :

It Honeycomb ceramic filters are designed for filtration of cast iron and nonferrous alloy. It has the characteristics: larger specific surface, high mechanical strength, and perfect heat-resistance performance. It can make the following result through filter: Purify metal liquid and get ride of non- metal impurity and gas. Make the filling type of the metal liquid steady and reduce the swirl. Simplify the pouring system and improve the producing rate. Reduce the air vent of castings and optimize and thin out metal organization. Improve surface quality of castings and mechanical performance. Reduce the rejection rate of castings, reduce the surplus of processing, raise the life span of the cutter and reduce casting cost.

Features:

- With good strength and thermal shock resistance,reduce breakage during pouring process.

- Good filtration effects,can remove impurities and improve the purity of molten metal

- Make metallic liquid laminar steady ,not turbulent flow ,prevent the air into the product.

- High-precision size is suitable for automatic production line,reduce the production cost.

Properties:

Density (g/cm3) :0.7--1.8

Compressive Strength(MPa) :>15

Coefficient of Thermal Expansion: <5x10-6k-1

Impact Thermal Resistance(800ºC):>5

Modulus of Rupture(MPa): 1.3--1.6

Softening Temperature Meet various casting temperature

Regular Sizes and Filtration Capacity

| Sectional Size (mm) | Aperture (mm) | Porosity (%) | Max filtration weight (kg) | Flow Rate (kg/sec) | ||

| Grey iron | Ductile iron | Grey iron | Ductile iron | |||

| 37×37×12.5 | Φ2.5 | 61 | 26-48 | 15-28 | 3~4 | 1~2 |

40×40×12.5 | Φ1.5 | 55 | 30-50 | 8-20 | 2-3 | 0.8-1 |

| Φ2.5 | 60 | 43~75 | 18~40 | 3~4 | 1~2 | |

50×50×12.5 | Φ2.2 | 58 | 65~90 | 19~30 | 3~5 | 2~3 |

| Φ2.5 | 60 | 70~100 | 20~50 | 3~6 | 2~4 | |

| 55×55×12.7 | Φ2.5 | 61 | 90~170 | 28~75 | 6~10 | 2~5 |

| 60×60×12.5 | Φ2.5 | 60 | 135~200 | 48~100 | 8~11 | 2~6 |

| 75×75×22 | Φ2.5 | 58 | 150~270 | 52~120 | 10~15 | 4~9 |

| 81×81×12.7 | Φ2.5 | 61 | 250~310 | 50~120 | 13~20 | 6~14 |

| 100×100×20 | Φ2.5 | 62 | 280~370 | 60~170 | 25~35 | 8~18 |

| 120×120×20 | Φ2.5 | 62 | 300~510 | 78~190 | 25~40 | 10~20 |

| 133×133×21.5 | Φ3.8 | 63 | 780~900 | 280~550 | 40~100 | 30~55 |

Φ40×12 | Φ1.5 | 57 | 32~42 | 22~33 | 2~3 | 1~2 |

| Φ2.5 | 59 | 33~67 | 31~41 | 3~4 | 2~3 | |

| Φ50×12 | Φ2.5 | 60 | 50~80 | 30~50 | 2~5 | 2~4 |

| Φ70×12 | Φ2.5 | 60 | 75~105 | 55~75 | 6~12 | 4~7 |

| Φ80×12 | Φ2.8 | 61 | 70~115 | 60~90 | 10~16 | 9~12 |

| Φ100×12 | Φ2.5 | 60 | 110~250 | 90~140 | 18~22 | 10~15 |

| Item | Unit | Al2O3 Ceramic |

| Alumina Content | wt% | 99.7 |

| Density | g /cm3 | 3.90 |

| Bending Strength | MPa ≥ | 450 |

| Working Temperature | °C | 1800 |

| linear expansion coefficient | ×10-6/°C | 8.0 |

| Insulation strength | Kv/mm | 12 |

| water absorption | % | <0.1-0.2 |

| Coefficient of Thermal Conductivity | W/m·K( 20°C) | 38 |

Detailed Images

Shipping

Lead time: 10-15days after signed the contract

Packing

- Inside packing: Filters are put in small box and Layered packaging. There is cardboard between each layer.

- Outside packing: Cartons&Pallets. Three layer corrugated cartons and export special pallets .

- The mark on cartons can be designed according to the customer's request.

FAQ

Q: Are you Factory?

A: Definitely, we are factory. Welcome to visit us!

Q: What Parameters should I provide to you for proper quotation?

A: Application, pore size, dimension, color, quantity, packing requirements, trade terms.

Q:How can you control your quality?

A:For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and we have the quality certificates with ISO9001.

Q: What is your lead time?

It usually needs about 15- 20 days after receiving the PO.

Q: Do you provide Samples?

A: Yes, our factory provide samples for testing, pls send detail parameters to us. (if customized, with drawing is best) The samples will be charged or free according to the specific requirements.

Q: What's the Payment Terms?

A: We accept T/T, L/C, West Union, etc.

Q: How can I get samples?

A: We are honor to offer you the samples.

Q: What about your Packing?

A: We provide plastic bag, woven bag, carton box, pallet, etc. OEM packing available too.

Q: Do you have R&D services?

A: Yes, we have R&D department to assist you in new product development.

Q:Does your company accept customization?

A:We accept OEM service.

Q:Can we visit your company?

A:Yes, for sure, you are welcome to visit our company.

Contact us

Cangzhou Sefu Ceraic New Materials Co.,Ltd.